Ningbo Newland-RS Plating Equipment Co.,Ltd

Ningbo Newland-RS Plating Equipment Co.,Ltd

Ningbo Newland-RS Plating Equipment Co.,Ltd

Creative display

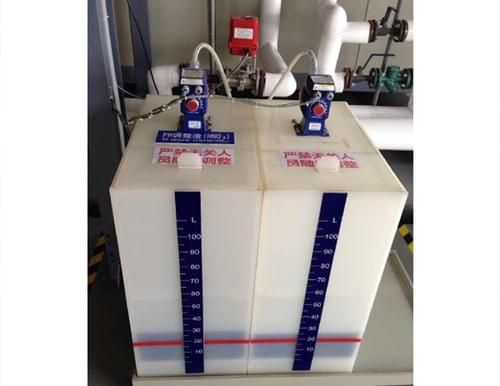

electroplating line auxiliary equipment

Electroplating line auxiliary equipment includes all necessary systems and components that support the main electroplating line, such as rectifiers, filtration systems, heating and cooling units, chemical dosing systems, rinsing tanks, drying systems, exhaust and waste treatment systems, and automatic control systems.View more details...

Single-Arm Electroplating Production Line

Cost‑Effective (Simple structure with lower investment cost)

Flexible Operation (Suitable for small‑batch and multi‑variety production)

Space Saving (Compact design requires minimal floor space)

Easy Maintenance (Simplified mechanical structure for hassle‑free upkeep)

Waste Gas Treatment System

High Efficiency (Effective removal of harmful gases and odors)

Stable Performance (Reliable operation with low maintenance)

Energy Saving (Optimized design reduces power and water consumption)

Compliance (Meets strict environmental protection standards)

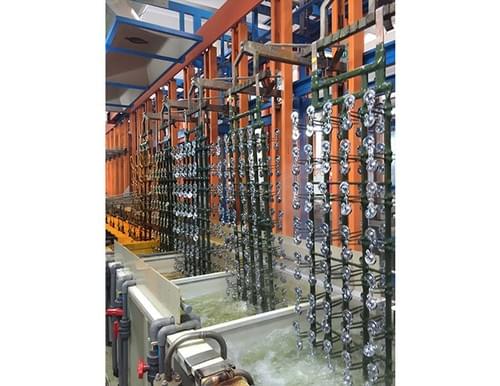

Automatic Barrel Plating Production Line

Designed for the hardware industry, our automatic barrel plating line offers a comprehensive one-stop solution. By combining high efficiency with precision process control, it guarantees superior coating uniformity and adhesion that exceeds industry requirements.

Automatic Circular Lifting Electroplating Production Line

High Efficiency: Continuous circular operation for maximum output.

Superior Quality: Precise control ensures uniform plating thickness.

Space Saving: Compact circular design optimizes factory floor space.

Easy Operation: Fully automated system for simple control and maintenance.

Automatic Gantry Electroplating Production Line

High Precision (Stable gantry movement for consistent plating)

Large Capacity (Suitable for heavy and large workpieces)

Flexible Layout (Customizable tank configurations)

Intelligent Control (User-friendly system for easy operation)

Automatic Anodizing Production Line

Superior Finish (Consistent oxide film quality and color)

High Efficiency (Continuous automated process for large‑scale production)

Precise Control (Accurate temperature and current management)

Smart Operation (Intelligent system for easy control and monitoring)

Ningbo Newland-RS Plating Equipment Co.,Ltd